Testing and Characterisation

Generally we provide standard testing and other analysis procedures as solely ordered jobs based on customer’s request or as a job within the R&D project.

Testing services mostly include material or assembly parameters and property verification. Especialy in electrical, optical, mechanical, thermal, frequency and visual definition.

Long term environmental testing can be provided according to your needs or industry standards using our testing chambers, specialized systems and devices.

We closely cooperate with other institutes and laboratories that allow us to utilize: X-ray, CT, electron microscope, certified labs etc.

We provide the following types of service:

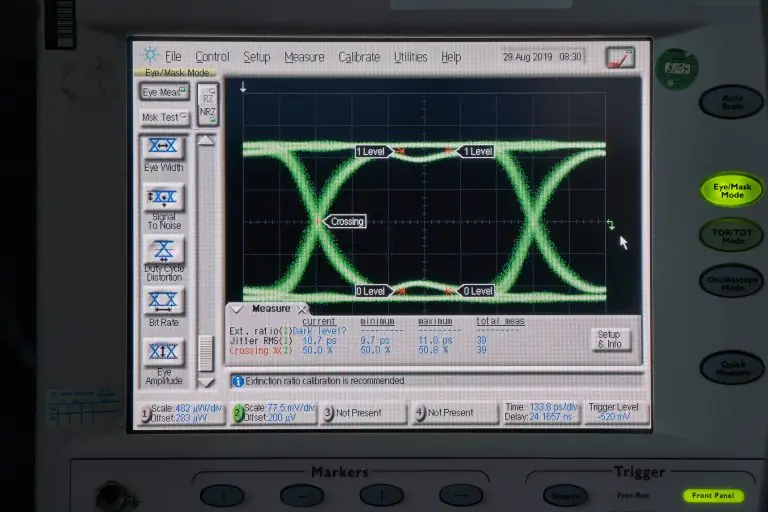

- Component characterisation (electrical, optical, high frequency)

- Qualification

- Burn-in

- Environmental testing (temperature and humidity)

- Ageing and stress tests

- Selected standard compliance testing (MIL, JEDEC, Telcordia)

- Mechanical tests (shear, pull)

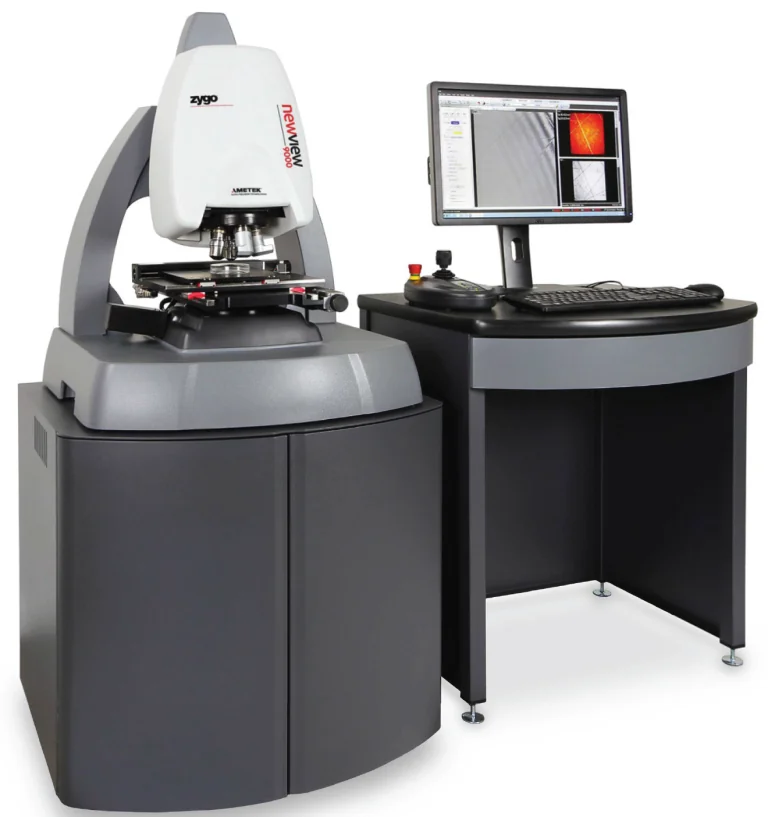

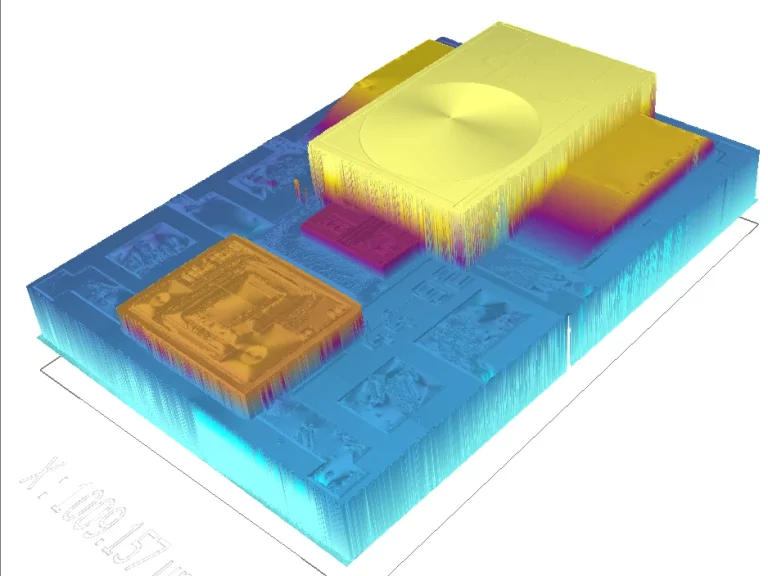

- Surface analysis (3D non-contact optical profile based on CSI and PSI method)

Typical application:

- Accelerated ageing tests

- Optical coupling characterisation and beam properties characterisation

- Electrical parameters characterisation

- High frequency characterisation s-parameters and time domain

- Visual inspection: X-ray, CT, Electron microscope

- Temperature cycling and shock tests

- Temperature and humidity biased and unbiased

Do you need more details?

How can we help you? Contact us directly here and give us a brief description of your project. We will get back to you as soon as possible.

Our Services

and Technologies

- Our technology can be used partially or as a complete assembly process.

- If you need to bring your idea to life, take a look at our R&D capabilities.

- We can provide Proof of Concept data on your prototype

if it is worth improving or not. - Do you lack the characterisation and test devices in your production or R&D?

Manufacturing

- Flexible volumes

- CM/OEM/ODM

- UV to MIR applications

- SiPh into TO package

- Complex packaging solution

- WLA and Component level Assembly

- PFMEA/Traceability/SPC

- Production data management

R&D services

- Simulations

- Feasibility study

- Packaging design

- Prototype builds

- Assembly process development

- Sample batch evaluation

- Private commercial projects

- Public funded projects

Testing services

- Characterization

- Qualification

- Burn-In

- Enviromental tests

- Shock temperature tests

- Accelerated ageing

- Selected standards compliance test

- Long term endurance tests